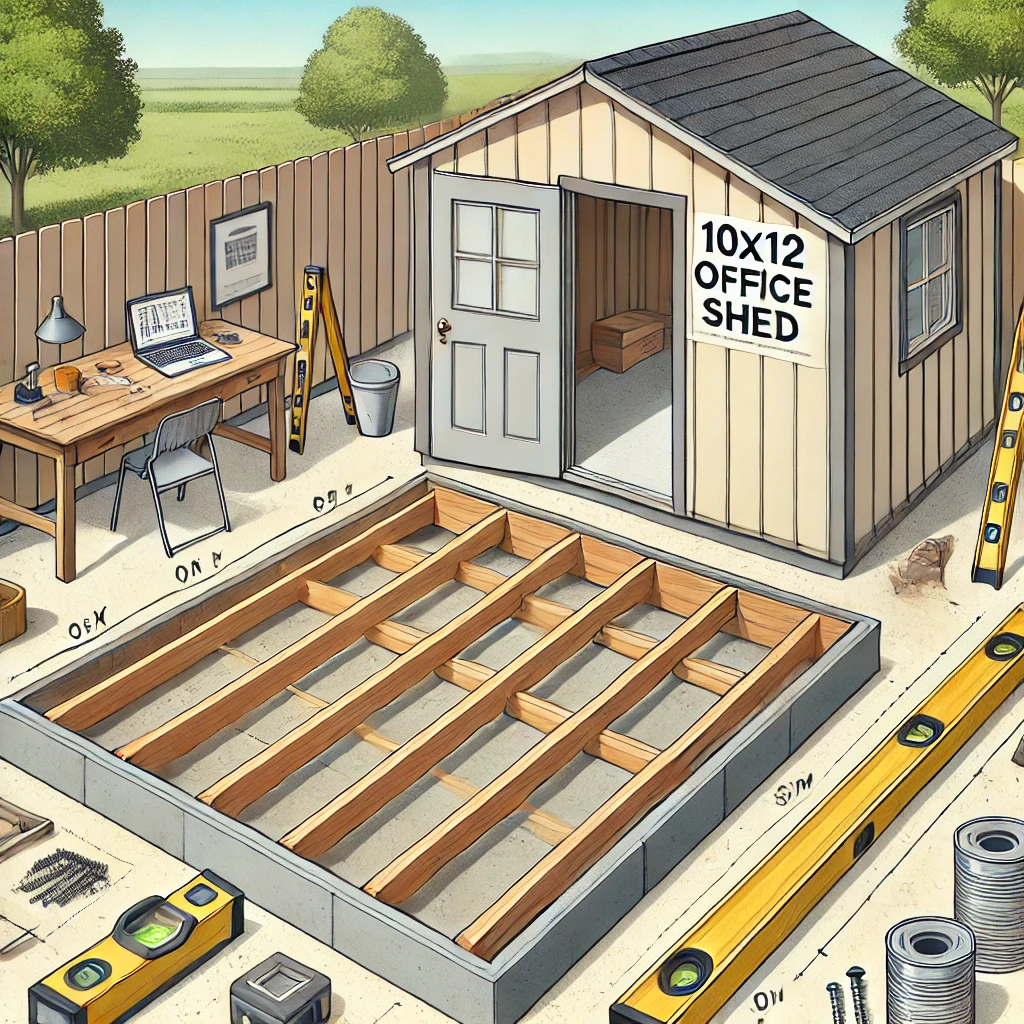

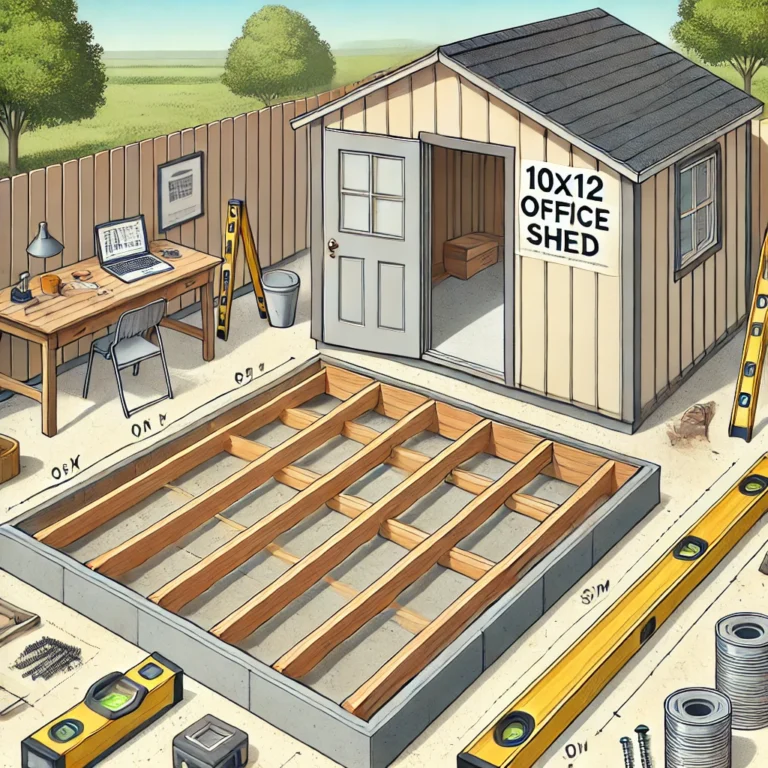

Step 1: Concrete Foundation Preparation

Foundation laying is the critical first step that determines the stability of your entire office shed. Here’s how to execute this crucial phase:

Materials Needed:

- Concrete mix

- Standard-sized bricks (approximately 150)

- Ground preparation tools

Detailed Process:

- Clear and level the ground where your shed will be situated

- Create precise trenches according to the shed’s 10’x12′ dimensions

- Fill the trenches completely with concrete

- Allow concrete to cure fully – this timing varies by brand, so carefully read package instructions

- Once cured, systematically lay standard-sized bricks across the foundation, ensuring even placement

Pro Tips:

- Check foundation levelness using a professional spirit level

- Ensure proper drainage around the foundation area

- Allow adequate curing time to prevent future structural issues

Step 2: Framing the Floor

With a solid foundation in place, you’ll now create the floor’s structural framework.

Materials Required:

- 1 1/2″ x 7 1/4″ pressure-treated lumber

- 8×5″ wood screws

- Carpenter’s square

- Measuring tape

Precise Construction Steps:

- Cut eight lumber boards exactly 9′-9″ long to serve as floor joists

- Carefully assemble the frame, maintaining precise right-angle connections

- Secure each beam using 8×5″ wood screws

- Use a speed square or carpenter’s square to verify 90-degree corner angles

- Double-check all measurements before final securing

Critical Considerations:

- Lumber must be pressure-treated to resist moisture and potential decay

- Precise measurements prevent future structural complications

- Ensure even spacing between joists for maximum floor stability

Step 3: Plywood Floor Installation

Now you’ll create a solid, stable floor surface over your carefully constructed frame.

Required Materials:

- 9/16″ plywood sheets

- 2″ wood screws

- Drill or screwdriver

Detailed Installation Process:

- Prepare plywood sheets:

- Three 4′ x 8′ sheets

- Three 4′ x 2′ sheets

- Position plywood carefully over floor frame

- Secure each plywood section using 2″ wood screws

- Ensure tight, even fitting with minimal gaps

- Verify complete coverage of floor frame

Installation Techniques:

- Start screwing from the center of sheets, working outwards

- Maintain consistent screw spacing (approximately 8-12 inches apart)

- Check for any uneven areas and adjust as necessary

Step 4: Front Wall Frame Assembly

Constructing the front wall involves strategic lumber placement to accommodate door and window openings.

Materials Needed:

- 1 1/2″ x 3 1/2″ and 3 1/2″ x 3 1/2″ pressure-treated lumber

- 2×3″ and 2×5″ wood screws

- Carpenter’s square

Precise Cutting Requirements:

- Six boards cut to 7′-2 3/4″ (studs)

- Two boards cut to 1′-5″ (studs)

- One board cut to 1′-4″ (bottom plate)

- One board cut to 7′-8″ (bottom plate)

- One board cut to 12′ (top plate)

- One board cut to 3′ (door header)

- Two boards cut to 5′ (window header and rough sill)

- Two boards cut to 6 3/4″ (cripple studs)

Construction Steps:

- Arrange lumber according to provided dimensional drawings

- Connect beams using appropriate wood screws

- Use speed square to confirm 90-degree angles

- Verify window and door opening dimensions

Strategic Considerations:

- Precise measurements ensure proper window and door functionality

- Pressure-treated lumber prevents moisture damage

- Consistent angle checks maintain structural integrity

Would you like me to continue with the subsequent steps in the same detailed manner?